An Open-source ventilator which can be reproduced with easily available components.This ventilator can supply uninterrupted mechanical ventilation for patients.This device is compatible with Ambu bag / self inflating bag

According to my calculation, a single prototype can be produced within 90 minutes (1.5 Hrs). Here is the breakdown of time

- The required laser cut pieces and 3D printed parts require a minimum of 1 hour (if printed on multiple machines)

- The assembly of the remaining parts can be done under 20-30 minutes.

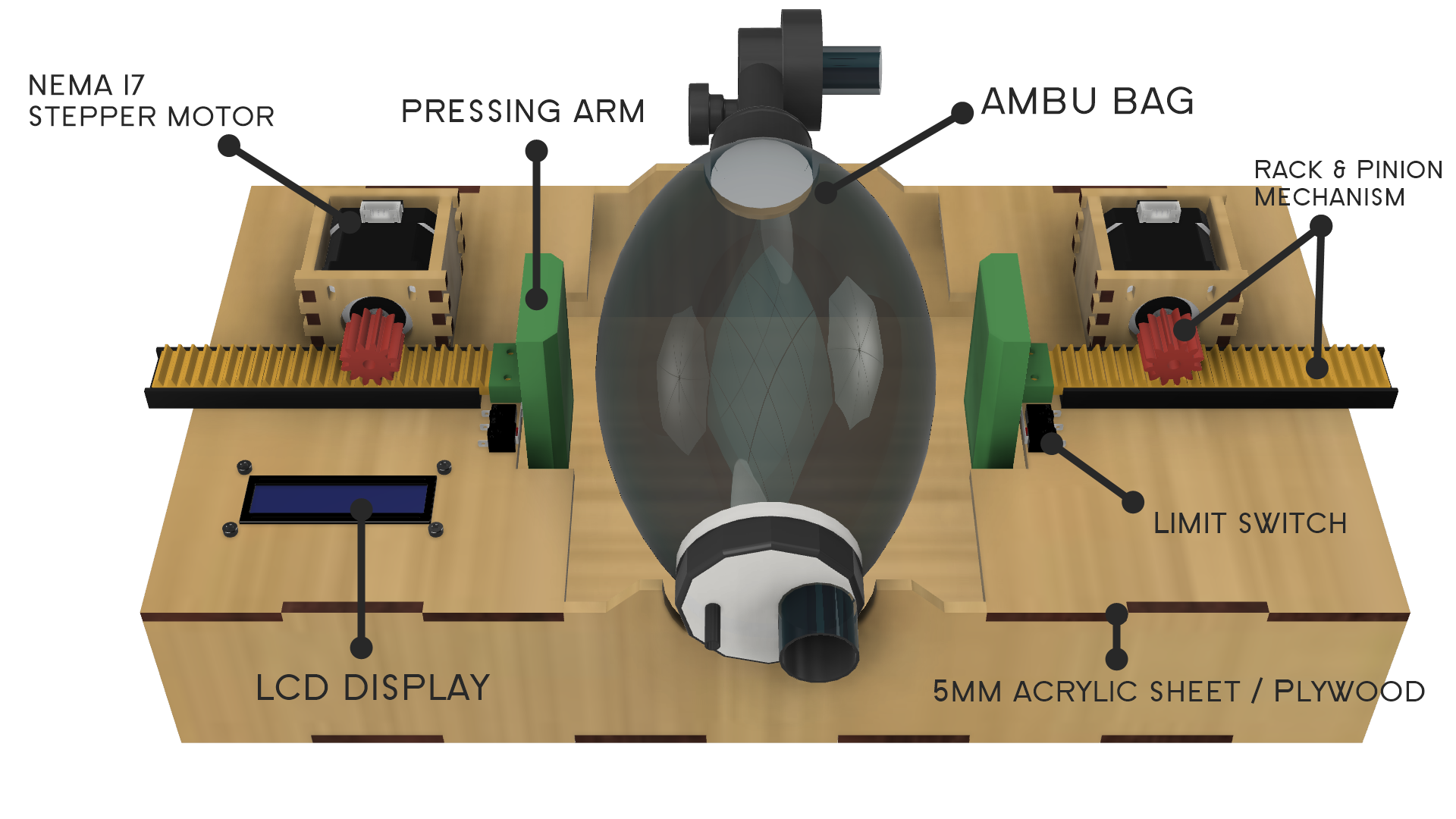

This prototype uses 2 Nema17 stepper motor (can be replaced using servo or even normal dc motor, depending upon the availability). Both motors are placed facing opposite to each other. The shaft of both motors is attached to a rack and pinion mechanism with a compressing Arm Block fixed to the end of both rack. Which compresses the 2 Arm Block when the motor is rotated in the opposite direction. An self-inflating bag or Ambu bag is placed in between the 2 Arm Block. So when the 2 block comes closer the bag will compress and act as mechanical ventilation and the cycle continues till the predefined time.

- Users can set the

durationandspeedof the compression and expansion cycle separately. [Under Progress] - Monitoring the status of the cycle on an LCD display.

- Limit switch is placed on both sides of the arm to get proper feedback of each cycle.

- If the Limit switch is not triggered it will alert the user with a buzzer, regarding the issue.

- Create the working simulation

- Start on prototype development

- Progamming

- http://oedk.rice.edu/apollobvm

- CAD Models

There can be lots of improvement made on this, looking for good contributions to make it better and more feasible